Australian Owned. Australian Manufactured.

Redefining the

coatings industry

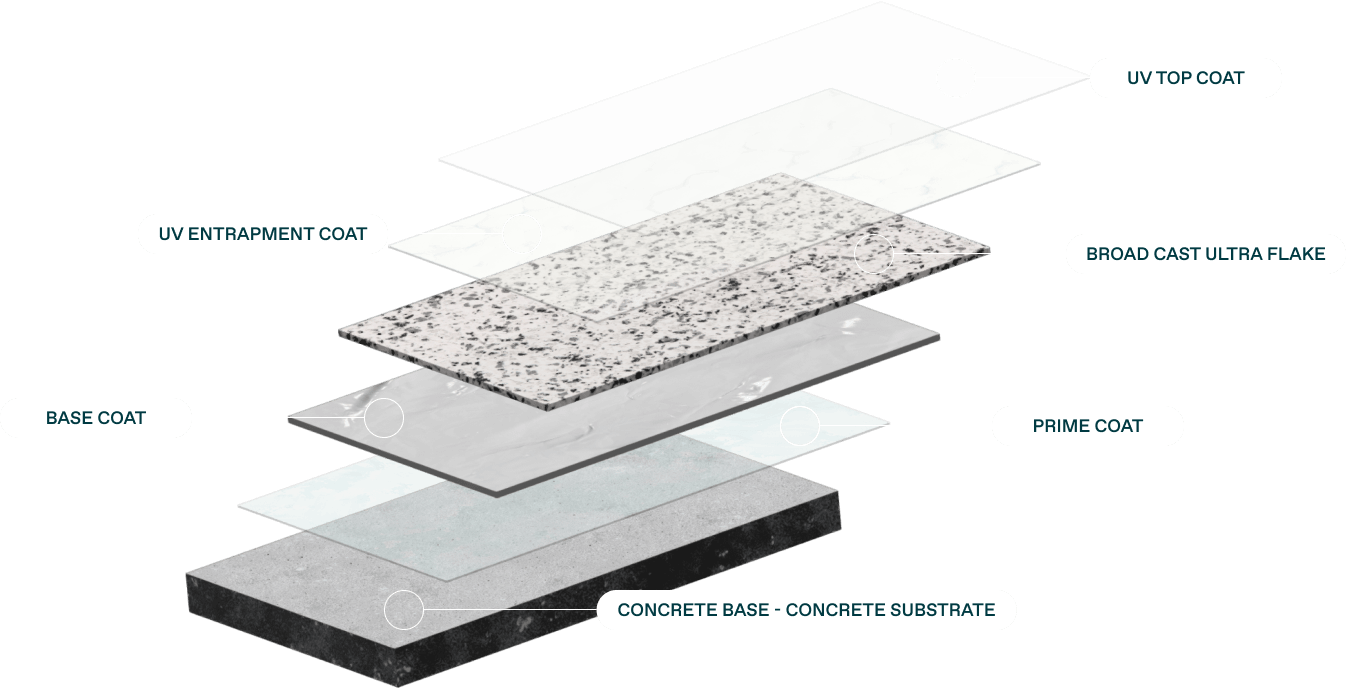

Ultra Flake System

Try our complete coating systems today

Revamp your space effortlessly with our Ultra Flake system – a low-maintenance, modern flooring and wall system perfect for both residential and commercial settings. Customize your floor with various slip-resistant additives, highlights or mica flake while providing a sleek, grout-free finish.

Colour studio

Find your perfect colour match

Disclaimer: While every effort is made to represent these colours as accurately as possible, different monitors and devices display colours differently. Keep this in mind when making colour choices based solely off online colour galleries.

All links below open in new window

Upcoming courses and events

Epoxy Training Course

Keilor East 18/09/2024 - 20/09/2024 Register Today More informationSome of our clients

ULTRA FLAKE RESIDENTIAL SYSTEM

Driveway Systems

APC Ultra Flake and Hyper Flake driveway systems offer a robust solution for enhancing and protecting driveways. With a long-lasting, weather-resistant finish, they shield against UV rays, chemicals, and abrasion, preventing cracks and prolonging surface life.

ULTRA FLAKE RESIDENTIAL SYSTEM

Swimming Pools

APC coating systems for swimming pool areas provide a resilient solution, creating a watertight seal that guards against pool chemicals and water damage. Their slip-resistant surface ensures safety, while resistance to UV rays and fading maintains a vibrant aesthetic.

Get in contact

Have a question? Reach out today

Fill out the form below and one of our friendly team will be in contact with you shortly.

follow along on instagram

Join 10K+ devoted APC followers

Our Instagram feed is packed with inspiration for your customers’ projects and with all the APC behind the scenes fun! Keep up to date with the latest trends in protective coatings, as well as product updates and events.